SPRUE ,SPECIFICATION,FUNCTION- short notes

HELLO DOCTOR VANAKKAM,

Warm welcome to stencildent family

Contents:

v Introduction to casting procedure

v Sprue

v Specification of sprue

v Methods to prevent

v Function of sprue

v HAND WRITTEN NOTES

Introduction :

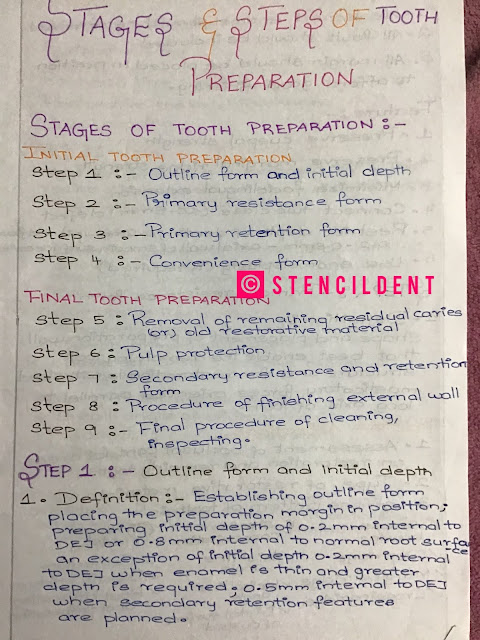

vCasting procedure steps:

1)

Tooth preparation

2)

Impression

3)

Die preparation

4)

Wax pattern

5)

Sprue former

6)

Casting ring liner

7)

Investing

8)

Wax elimination and

burnout

9)

Casting

10)Quenching

11)Sandblasting

12)Finishing and polishing

SPRUE

· It’s a channel created in the

investment through which molten alloy enter the mould space which is created

due to burnout of wax pattern.

· Sprue former are material used to

form sprue

· They are made up of wax, metal,resin.

SPECIFICATION OF SPRUE:

1) SPRUE DIAMETER:

Ø Same a size as thickest area of wax pattern

Ø If large cause distortion

Ø Small : suck back porosity

2) Sprue position :

Ø At greatest bulk in pattern

Ø The reasons are :

Ø To permit flow of alloy into the

mould cavity

Ø To avoid distorting thin areas of wax

3) Sprue length:

Ø In gypsum bonded investment material up

to 6mm

Ø For phosphate bonded investment

material about 3-4 mm and it should be placed in centre of ring

1) SPRUE DIRECTION:

Ø proximal surface -45 degree

Ø 135 degree to axial wall pattern

Methods

to prevent:

§ Air entrapment

§ Occurrence of suck back porosity

Functions

of sprue :

ü It forms mount for wax pattern

ü Channel for elimination of wax

ü Entry of molten alloy during casting

ü Compensate shrinkage during

solidification

I Hope this short notes must have helped you if it had helped you do let

me know in the comment section below as this will motivate me to post more such

content

For further contact me through contact information provided in the

contact us page .

Thank you have a wonderful day

❤

ReplyDelete