ZINC PHOSPHATE CEMENT - CLASSIFICATION,COMPOSITION,SETTING REACTION,MANIPULATION

Zinc Phosphate Cement

- ADA Specification number of Zinc Phosphate is 96.

- Zinc phosphate cement was originally developed more than 100 years ago and was extremely popular during most of the twentieth century.

CLASSIFICATION:

TYPE 1 : Fine grained for luting

Type 2: medium grained for luting and restorative purpose.

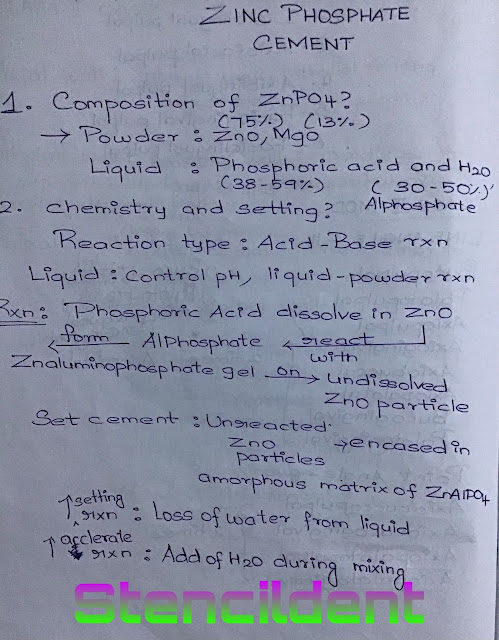

COMPOSITION:

- Zinc Phosphate cement contains powder and liquid containers which comes separately.

liquid: phosphoric acid 38-59% in water 30-50% and is buffered with aluminium and zinc salts to control the ph.,zinc- 7%,aluminium-2%

CHEMISTRY AND SETTING :

REACTION TYPE- ACID-BASE REACTION

SETTING REACTION:

Phosphoric acid dissolve in zinc oxide react with aluminum phosphate to form zinc aluminophosphate gel on undissolved zinc oxide particles

set cement: unreacted zinc oxide particles gets encased in amorphous matrix of zinc aluminophosphate.

- loss of water from liquid increases the setting reaction

- addition of water during mixing accelerate reaction

MANIPULATION:

- Powder should be divided into increments and added to liquid

- Brisk spatulation using considerable area of glass slab with each increment spatulated for 15-20 second

- Mixing time 1-5 to 2 minutes

- Use of properly cooled thick glass slab will dissipate heat.

METHODS TO INCREASE THE WORKING TIME OF CEMENT

FROZEN SLAB TECHNIQUE:

- Its, employed to increase the working time ,as zinc phosphate cement is a exothermic reaction in order to dissipate the heat and to cool down this technique is followed.

- In this method,a glass slab is cooled in refrigerator at 6 degree celsius or freezer at minus 10 degree celsius

- Employed during cementation of multiple orthodontic treatment ,long span bridges ,where longer working time and shorter setting time is required

- Powder and liquid are dispensed onto the slab without removing condensed moisture

- Amount of poder incorporated in this method is 50 to 75 %more than normal

- Lower viscosity cement facilitates the setting of multiple unit cast restoration.

- However ,incorporation of condensed moisture into mix counteracts the higher powder to liquid ratio,hence compressive and tensile strength decreases

- Working time is increased by 4 to 11 minutes

- Setting time is shortened by 20 to 40%

POWDER LIQUID RATIO: 1.5g To 0.5mL

CLASSIFICATION OF CEMENT :

- STRENGTH; STRONG,WEAK

- USES : RESTORATIVE,LUTING,PULP PROTECTION

- PRIMARY COMPOSITION: PHOSPHATE,PHENOYLATE,RESIN BASED,POLYCARBOXYLATE

BIOLOGICAL PROPERTIES

Pulp response is moderate pH IS 2 initial and 5 after luting.

ADVANTAGE:

- High compressive strength 120 mpa at 24 hours

- does not dissolve in oral fluid

- good thermal insulation ability

- The molecular size of phosphoric acid is smaller than that of dentinal tubule,hence it can cause an adverse pulpal reaction when used in deep restoration

AIM OF THIS POST :

zinc phosphate cement: classification,composition,setting reaction,methods to increase working time of cement , frozen glass slab, biological properties ,advantage and disadvantages of zinc phosphate cement .

Hope you all got enlightened about zinc phosphate if this post helped you do let me know in the comment section below

For any product endorsement contact : stencildent@gmail.com.

THANK YOU

Please upload the remaining cements and all dental notes so that I can pass in exams

ReplyDeletehi my dear stencildent family member here you go with your request https://www.stencildent.com/2024/08/zinc-polycarboxylate-cement-frequently.html kindly do share in your valuable feedback to and sorry for the late post .

Delete